Our Services

New Product Introduction

We partner with you to streamline and optimize your product design, manufacturing, and supply chain, saving you time and money while ensuring uncompromising quality.

Through our expert New Product Introduction (NPI) services, we accelerate your product’s journey from concept to market. As your trusted contract manufacturer, we bring your product to market efficiently, aligning with your values and needs through our Lean processes and Industry 4.0 innovations.

Quick Turnaround

In today’s landscape, getting your product from concept to market dominance demands a partner who not only meets the speed of innovation but leads it.

For your high-volume needs, our tailored solutions ensure quick and precise delivery – meeting your tightest deadlines without compromising on excellence.

Trust in our unwavering commitment to quality and efficiency as we accelerate your vision and bring it to life, driving your success into the future.

Assembly Services

To contribute to the world’s most advanced products, we don’t just meet expectations – we surpass them. We continually evolve our technology, equipment, and practices to stay at the forefront of innovation, delivering unmatched assembly services.

With cutting-edge SMT technology, SPI (solder paste inspection), Level 4 part traceability, and 3D printing, we ensure precision and quality at every stage. Partnering with you to meet your goals, we leverage these advanced resources to bring your vision to life with unparalleled efficiency and excellence.

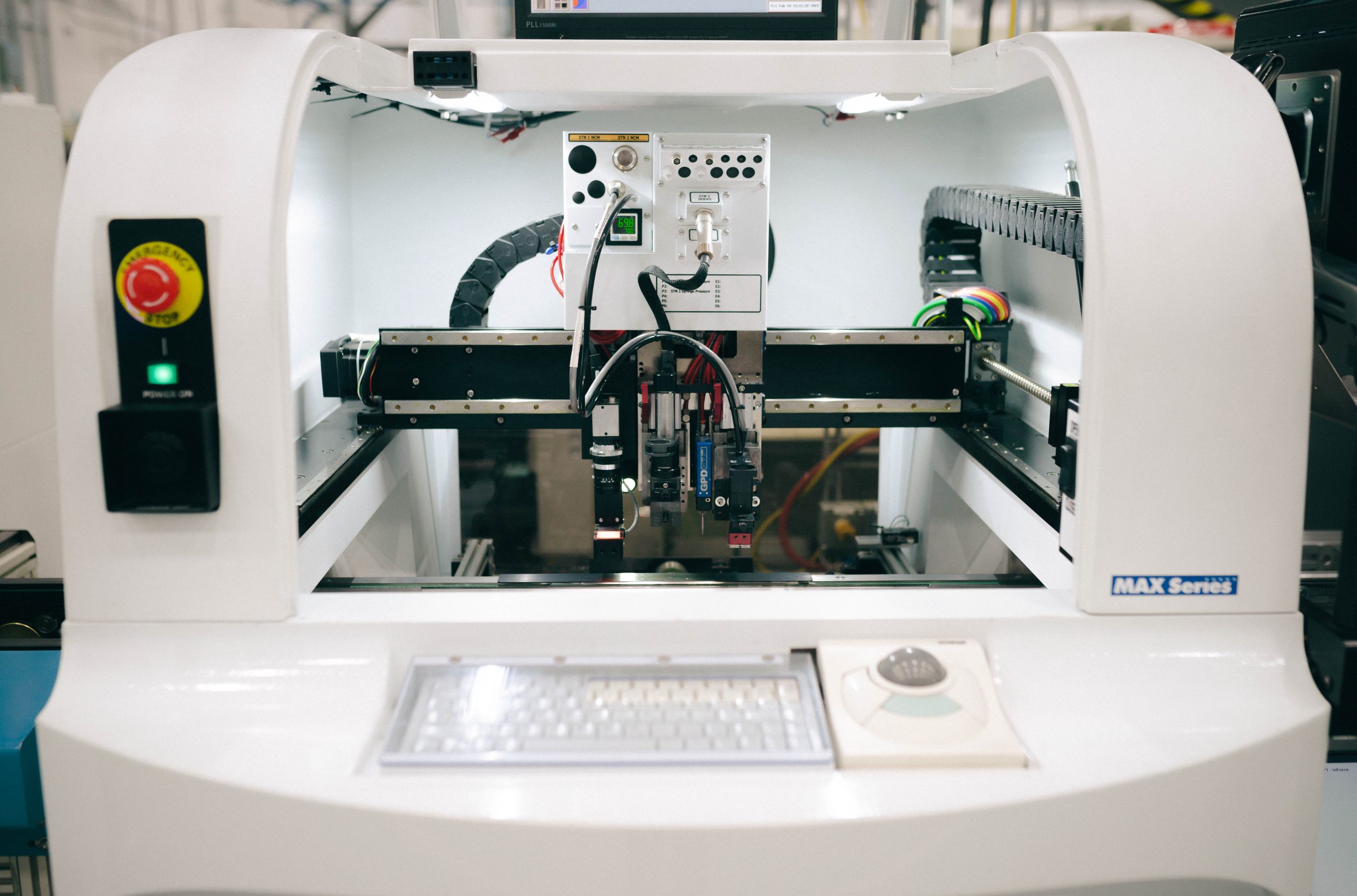

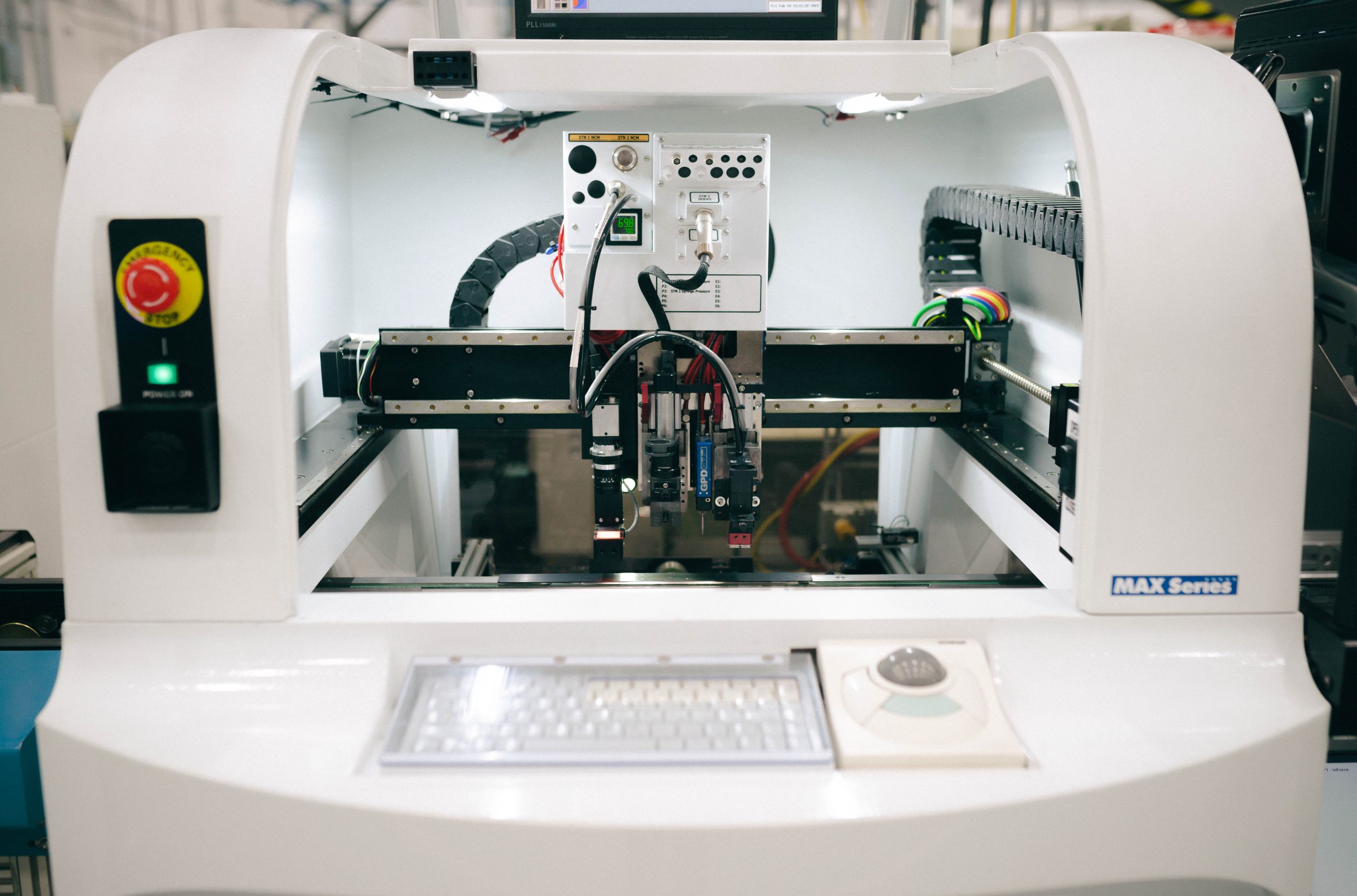

Printed Circuit Board Assembly

At DSM, our state-of-the-art facilities integrate advanced robotics, automation, and Six Sigma lean manufacturing to bring your product to life with unmatched precision. From day one, our printed circuit board assembly (PCBA) services have been designed for industry-leading, highly complex technological products. With capabilities such as 01005 and uBGA component placement, SPI (solder paste inspection), x-ray inspection, wave and selective soldering, and advanced real-time AOI process feedback, we ensure every board we assemble meets your highest standards. Whatever your requirements, DSM’s expertise and cutting-edge technologies are here to deliver superior performance and quality.

Final Assembly

From communication and GPS products to high temperature downhole tool assemblies, we can create your product from start to finish. Our final assembly services include:

- Functional test

- Electro-mechanical assembly

- Protective coatings

- Custom cables and harnessing

Supply Chain Services

Sourcing, storing, managing, and distributing the parts are just as important as the final assembly. We work with you to create a customized supply chain model that maximizes efficiency, quality, and cost savings specifically for your product.

We’ve created supply chain systems for customers who didn’t fit within the typical mold, adding in two-way signaling systems, Kanban replenishment, in-house consigned stores, and advanced inventory tracking.

Turnkey Solutions

We have readily available vendor-managed inventory on-site for your production needs, led by authorized distributors. Our advanced ERP system gives our experienced procurement team the ability to plan effectively for material demands, deliver on time, and secure the best price for your components, allowing you to focus on the skills that set you apart.

We also utilize the POURS system. This highly-advanced program allows us to connect directly with our customers’ network and plan for supply chain needs. This gives us increased visibility, accuracy, and collaboration with our customers.

Advanced Material Tracking

Building highly-complex products means traceability is key. Using Cogiscan’s advanced real-time traceability system, we have immediate visibility of every part in the facility. This automated technology takes lean manufacturing one step further and provides full product traceability down to the component and designator level.

For our customers, this means 100% accuracy and efficiency in your product builds. Time is spent on what matters – building you a quality product.

After-Market Services

Your customers expect more – uninterrupted service, world class products, and top-notch customer service. We partner with you to not only build products to the highest standards of quality, but to offer support and peace-of-mind that extends far beyond the initial purchase.

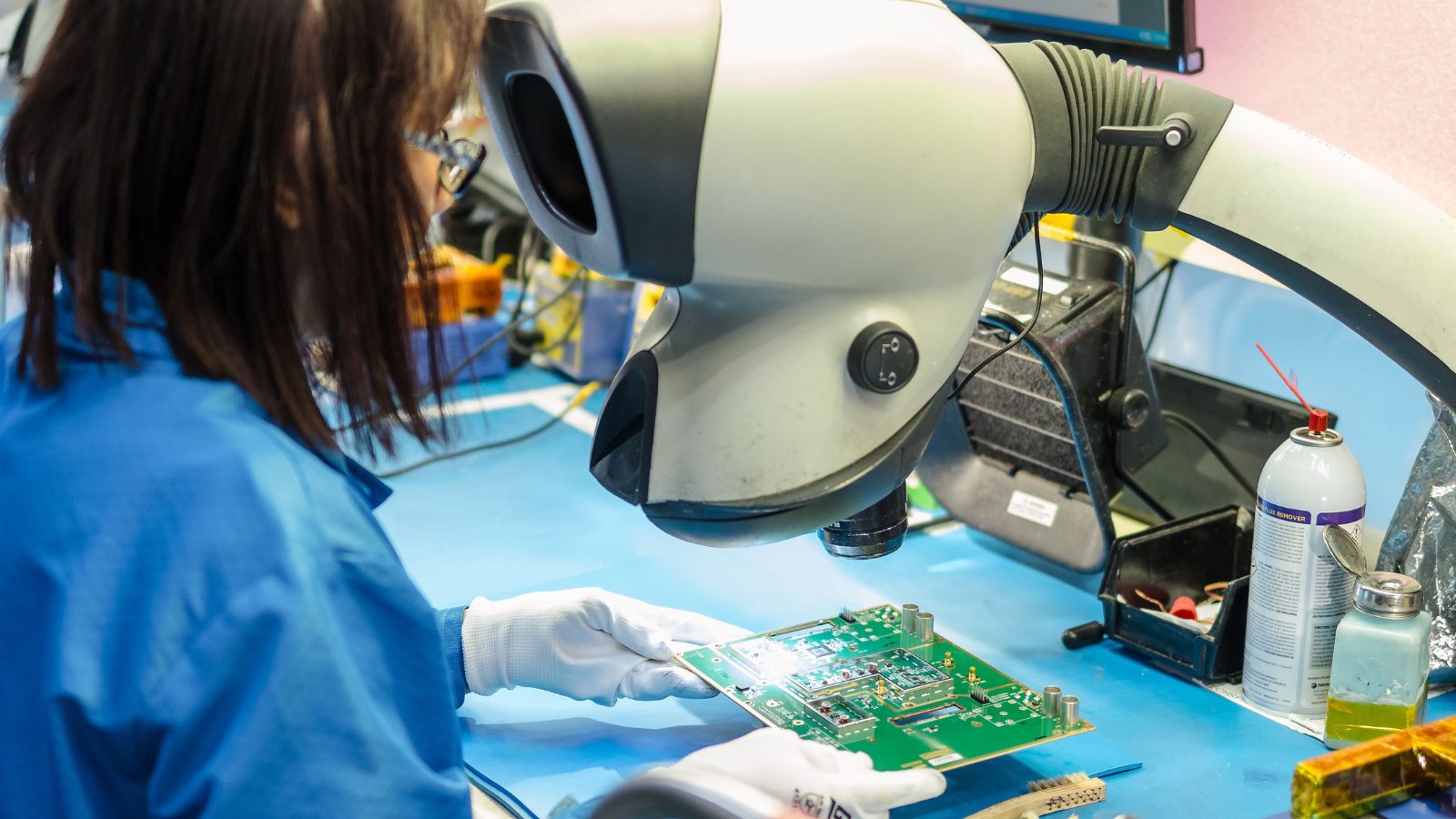

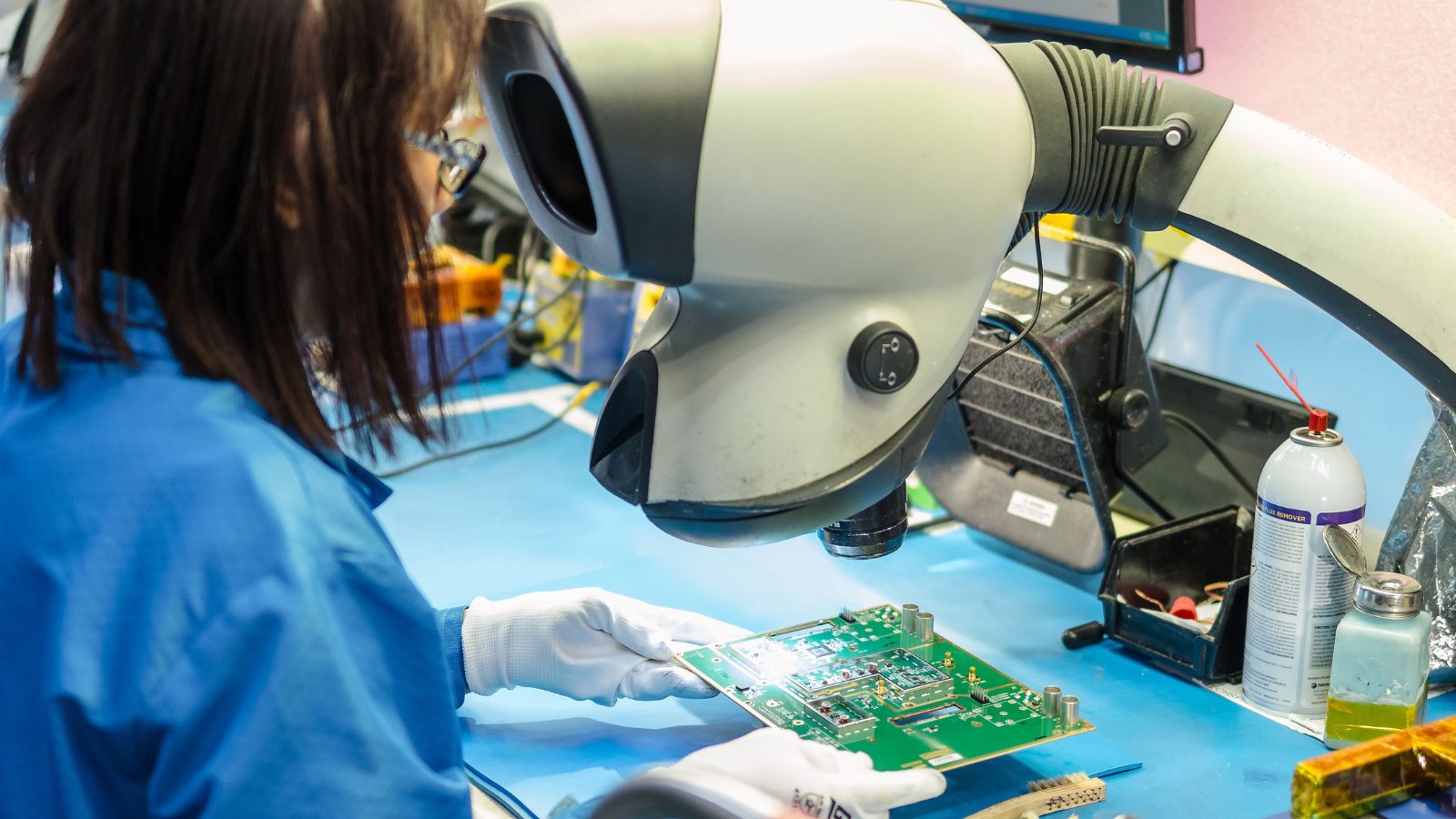

Repair Services

The repair centre within DSM is designed to handle both warranty and off-warranty repair services. We can help manage your RMA process and provide upgrade, refurbishment and repair services for your products, directly to your customers. Our services also include testing and diagnosing field faults, performing firmware and engineering updates, with complete repackaging of serviced products.

Product End-Of-Life Support

We keep close tabs on the supply chain of your product to plan ahead for manufactured discontinued parts, last time buys, and supply interruption. We are proactive in this process – we will advise you of any upcoming obsolescence and work with you to manage material based on the life cycle of your product. We ensure your production runs smoothly with no unknown variables.