Strengthen Your Supply Chain and Navigate Tariffs with Confidence

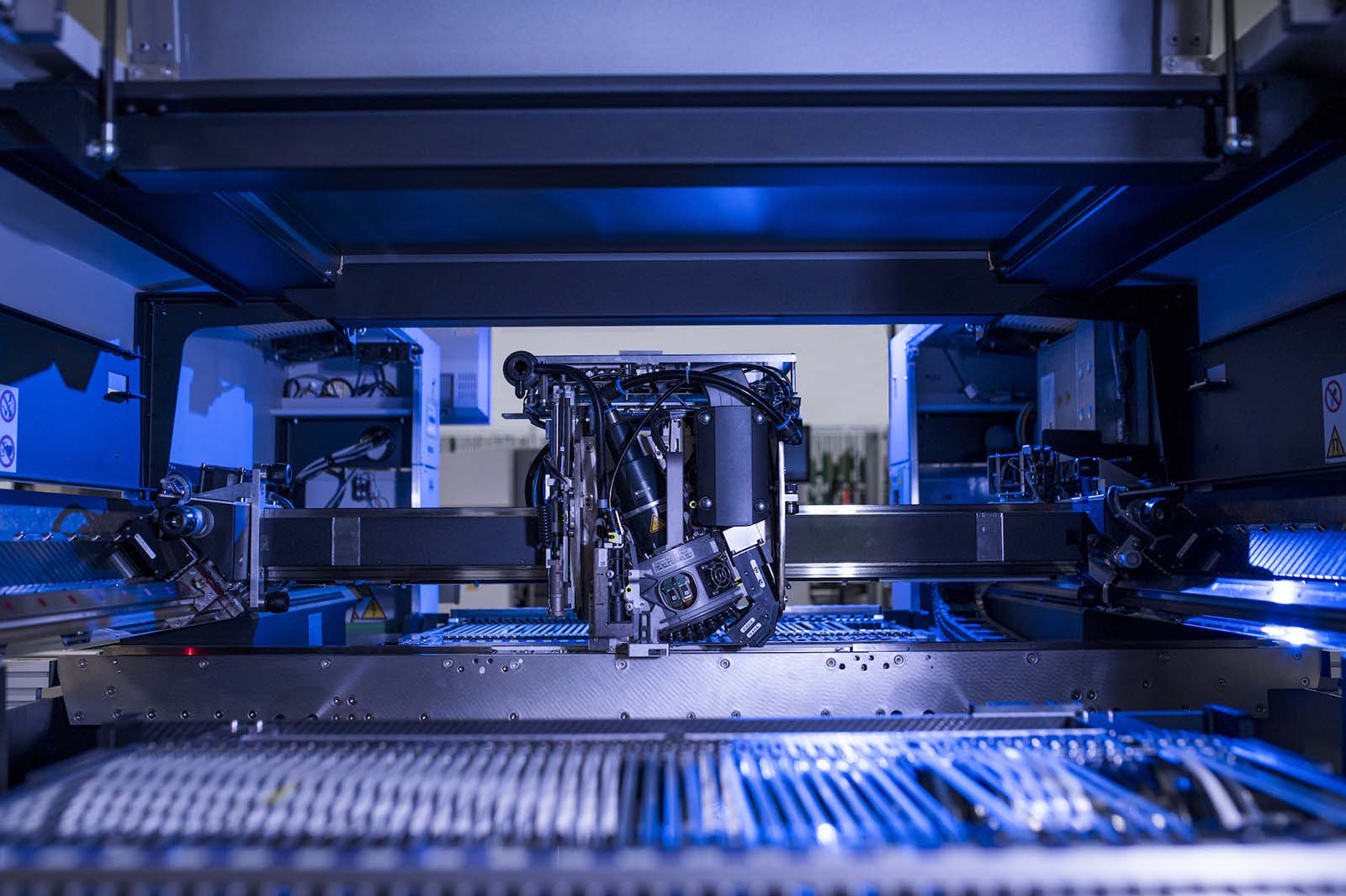

Shifting tariffs and supply chain disruptions create uncertainty, but with the right manufacturing partner, you stay in control. DSM delivers cost-effective, flexible solutions that help you mitigate risk, maintain efficiency, and ensure quality.

With facilities in both the U.S. and Canada, DSM provides agile, tariff-resilient manufacturing tailored to your needs. Together, let’s build a smarter, more secure production strategy.

Ready to take the next step?

Connect with our team to explore how our flexible, North American manufacturing solutions can support your business.